Web Content Viewer

Web Content Viewer

Print Finishing and Embellishment Applications

Many printers have found that trying to maintain their profit margins just on the basis of print quality is a losing proposition. As a result, there’s been a growing appreciation of the value that the techniques of embellishment are proven to add.

Embellishments such as foil stamping, diecutting, embossing, and specialty coating aren’t new; commercial lithographers and packaging printers have offered them for years. Now, however, they’re also available to digital printing for short-run, customized, and personalized applications.

Embellishment heightens visual appeal, but it adds much more than an eye-catching surface appearance. It also delivers measurable, profit-driving results: an outcome that the industry’s packaging segment knows well. In this section we'll focus on the most common finishing and embellishment services as well as some of the specialty applications and how Canon Solutions America can help you produce those.

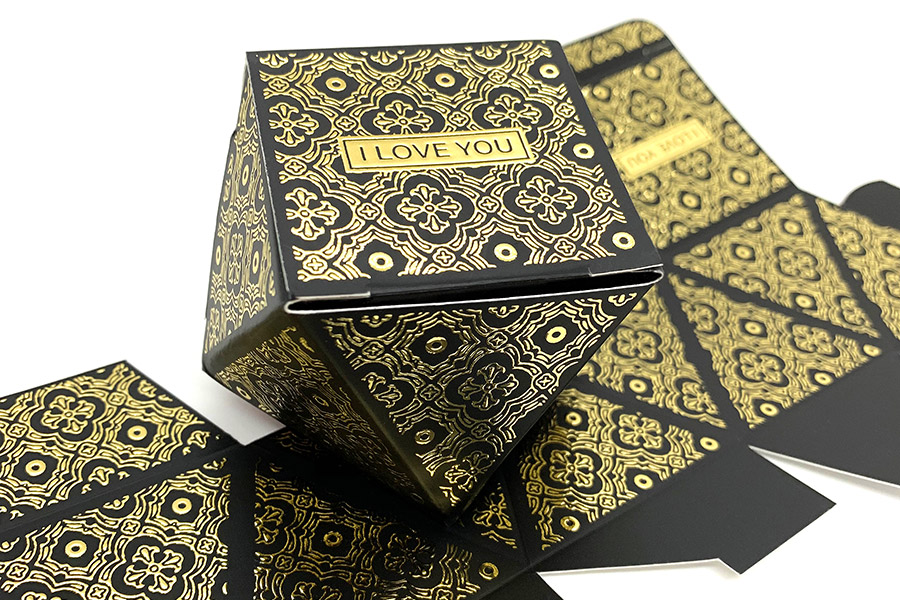

Foiling

From the ancient art of gold beating to the radiant surfaces increasingly seen on substrates of all kinds today, nothing says “upscale” more convincingly than adding reflective highlights in gold, silver, holographic, and other metallic finishes to twodimensional print. Some digital presses can deposit metallic toners as part of the print run. However, metallizing digital print more commonly takes place as an offline process that achieves the effect by applying foil.

The technique isn’t complicated—foiling can be bonded to individual pieces of print using desktop laminators. For production in quantity, however, hot stamping and cold foiling are the established methods. Hot stamping typically takes place separately from the printing. Cold foiling is performed inline as part of the conventional press run. It can be added to digital output along with other embellishments after printing.

Diecutting

Presswork imparts content to a printed piece. Diecutting adds shape that gives both subtle and explicit clues to the message the piece is meant to deliver. Decorative “sculpting” with cut-out windows, filigree outlines, and other fancy alterations connotes sophistication, luxury and distinctiveness—all calculated to heighten engagement with the piece and reinforce the call to action it contains.

Unlike other forms of embellishment, diecutting is a subtractive process: its visual impact comes from what it takes away from the initial printed piece, not from anything it adds. Nevertheless, in order to achieve the desired effect, the application of diecutting must be as precise and creatively flexible as any other embellishment technique.

Embossing

Marketers increasingly recognize haptics—the branch of neuroscience concerned with the sense of touch—as a key to consumer engagement. Research indicates that someone who picks up and reads a printed piece probably will recall its contents better than someone who gets the same information from a screen. Retailers know that a shopper who grasps an item on a store shelf is more than likely to buy it, because to touch something is to mentally take ownership of it.

UV Coating

Ink or toner on paper supplies the image. Specialty fluids laid down over the colorant add the pizzazz. They also protect printed surfaces, enabling printed products to stand up better to handling and (if they are postal pieces) to their journey through the mailstream.

Printers use a variety of specialty fluids to make finished pieces scratchproof and rub resistant. The fluids also create surface effects that enhance appearance with gloss, matte, and dull finishes. Gloss reflects light; matte scatters it; dull subtly tones down color and contrast. The finishes can be used in combination to make the effects even more visually interesting.

Sleeking

Sleeking is a digital print finishing method that involves a special image transfer that specifically bonds to digital inks on many printed surfaces, allowing the ability to create dynamic special effects and designs. Offers on-demand spot coating for digital prints with gloss, matte, silver, gold or holographic effects. Hot foil stamping and sleeking can be used across all kinds of materials, whether with simple finishes like gloss or matte, metalized backgrounds like gold or silver, or dramatic holographic impressions in spot locations or full coverage.

Sleeking can be used for wedding cards, invitations or greetings Cards.

Benefits of Sleeking:

- Visual Attraction

- Special Effects

- Protection

- Tactile Enhancement

Specialty Applications

Bumper Stickers, Counter Cards, Door Hanger, Header Cards, Tags, Tickets, Bookmarks, and more.

Interested in How FINISHING AND EMBELLISHMENT Can Help Your Business?

Fill out the form below to speak with a representative.